Isiphelo se-spherical end mill sisixhobo esiqhelekileyo esisetyenziselwa ukusika, esineempawu ezininzi ezizodwa kunye neenzuzo.

Inkcazelo emfutshane:

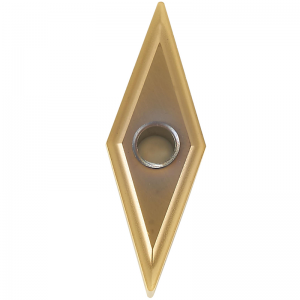

Isiphelo se-spherical end mill sisixhobo esiqhelekileyo esisetyenziselwa ukusika, esineempawu ezininzi ezizodwa kunye neenzuzo.Oku kulandelayo yinkcazelo ethe kratya yentshayelelo yobugcisa kunye noncedo lwelitye lokusila elintlangothi-mbini elingqukuva: Faka iJiyometri: Izixhobo zokusila zebhola zizodwa kufakelo lwazo lwejiyometri ezinefilidi ezimbini.Umphezulu wokuphela kwe-blade yi-spherical, eyenza indawo yokusika ibe mkhulu kunye nokusabalalisa amandla okusika ngokulinganayo.Le geometry inika kwakhona indawo yokusika elula, ukunciphisa i-burrs kunye namanqaku ngexesha lomatshini.Izinto ze-Blade: I-blade yomgca wesibini we-spherical end mill ngokuqhelekileyo yenziwe nge-high-speed steel, i-alloy eqinile okanye i-cubic boron nitride.Ezi zixhobo zinobunzima obuhle kakhulu kunye nokuxhatshazwa kokugqoka, okunokugcina ubukhali becala lomese kunye nokwandisa ubomi bomese.Uyilo lwe-Edge: Uyilo lwecala lwemiphetho emibini ye-spherical end mill yenza kube nokusebenza okugqwesileyo kokusika.Umgca wokusika udla ngokuyilwa nge-angle edge edge, enokunciphisa amandla okusika kunye nokungcangcazela ngelixa uphucula ukusebenza kakuhle.Ukongezelela, ukuchaneka komgca wokusika kuphezulu, okunokubonelela ngokuchaneka okuphezulu komatshini kunye nomgangatho ophezulu.Ukukhetha inani leefluti: Iinqwelo zokusila zebhola ezineefluti ezimbini zinokubonelela ngeendlela ezahlukeneyo ngenani leefluti.Ukukhethwa kwenani leefluti kuxhomekeke kwiimfuno ezithile zomatshini kunye nezinto zokusebenza.Ngokubanzi, iifluti ezininzi zibonelela ngokusetyenzwa okuphezulu kokusika kunye nemigangatho egudileyo eyenziwe ngoomatshini.Nangona kunjalo, iifluti ezininzi zinokunyusa amandla okusika kwaye zichaphazele uzinzo lwesixhobo.Imimandla yesicelo: I-spherical end mill ene-spherical end mill ifanelekile ukusika izinto ezahlukeneyo zetsimbi, ezifana nentsimbi etyhidiweyo, intsimbi, insimbi engenasici, i-aluminium alloy, njl. iindawo ezigobileyo kunye nezakhiwo ezinzima.Izinto eziluncedo: Iintsimbi zokuphela kwebhola ezinefilidi ezimbini zibonelela ngeenzuzo ezininzi.Okokuqala, i-blade inendawo enkulu yokusika kunye nokusabalalisa okufanayo kwamandla okusika, okunokuphucula ukusebenza kakuhle kunye nomgangatho wokucubungula.Okwesibini, ukukhethwa kwezinto ze-blade kunye nenani lamaphethelo anokulungelelaniswa ngokweemfuno ezithile zokucwangcisa ukufezekisa ukusebenza kakuhle kwemveliso kunye nokuchaneka kokusebenza.Ukongeza, umphetho wesibini we-spherical end mill unokunciphisa ii-burrs kunye namanqaku ashiyekileyo, kwaye unike umphezulu owenziwe ngoomatshini.Ukushwankathela, umgca wesibini we-spherical end mill uneempawu ezizodwa zobugcisa kunye neenzuzo ezininzi, kwaye zifanelekile ukusika izinto ezahlukeneyo, ngokukodwa ukuqhutyelwa kwezinto ezizii-spherical and curved.Uyilo oluphuculweyo lwejiyometri yeblade, imathiriyeli yeblade, uyilo lweblade kunye nokukhethwa kwenombolo yomphetho kwenza enye yezixhobo eziyimfuneko ekusikeni.